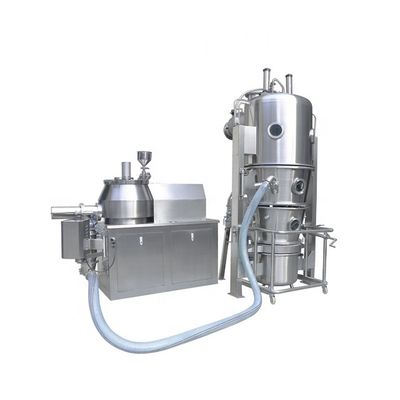

1,The structure of fluidization bed is round so as to avoid the dead angle

2,Inside the hopper there is a stirrer in order to avoid agglomeration of raw material and forming canal of flow

3,The granule is discharged through the method of turning over. In this way it is very convenient. The discharging system can be designed as required too

4,It is operated at the condition of negative pressure and seal. The air is filtered. Therefore it is simple in operation and convenient in clean. It is an ideal equipment that is in conformity with the requirements of GMP.

5,The drying speed is fast and the temperature is uniform. In general, the drying time is 15-45 minutes each batch.

Typical application:

1.Granulation in the refrigeration industry: tablet granules, granular granules, capsule granules.

2. Granulation in the food industry: cocoa, coffee, milk powder, granular juice, condiments, etc.

3.Granulation in other industries:pesticides, feed, fertilizers, pigments, dye chemicals, etc. Drying of powdery or granular wet materials.

Coating: granule, pill protective layer, color preparation, film, enteric coating, etc..