Type:

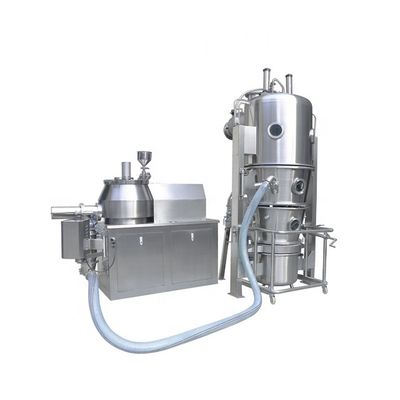

Fluid Bed Drying Equipment

Application:

Medicine Processing, Chemicals Processing, Plastics Processing, Food Processing

Condition:

New

Voltage:

380V/460V/Customizable, Client Local Standard

Power:

See technical parameters

Dimension(L*W*H):

See technical parameters

Key Selling Points:

Multifunctional

Warranty:

1 Year

Weight (KG):

See technical parameters

Applicable Industries:

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Bevera

Showroom Location:

None

Marketing Type:

New Product 2020

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Bearing, Pump, Gear, Motor, Gearbox, Engine, Pressure vessel

Heating Method:

Electric Fuel Oil Gas Heating

Material:

SUS304, SUS316

Product Name:

Medicine Powder Boiling Granulator

Function:

Mix / Granulate / Dry

Application Field:

Chemicals Foodstuff Medical Pharmaceutical Industrial Processing

Application Material:

Powder/Granule

Equipment Material:

Stainless Steel304/316/Carbon Steel

Heating Source:

Electricity Steam Oil Gas

Advantage:

Easy Operation High Efficiency

MOQ:

1set

After-sales Service Provided:

Service Machinery Overseas, Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

After Warranty Service:

Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:

None

Certificación:

CE/ISO9001

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!